Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Description

High-quality ceramic tile products are a necessary prerequisite for determining the decorative effect. Then, the standardized paving construction of tiles can be regarded as the finishing touch in the decoration project. Therefore, the laying of tiles is not only a technical work, but also a very particular craftsmanship, which is a creative artistic creation of plane space. Here are some artistic expressions of bricklaying with metal strips.

The perfect fusion of metal strips and tiles enhances the three-dimensional effect and gives the tiles more vitality.

Sealing the edges of the tiles with metal strips not only adds a layer of protection to the edges and corners of the tiles, but also makes the layers of the tiles more distinct.

Just stick the edge of the metal strip to the tile, and the existing edges and corners can be hidden and covered.

The following is a design analysis of the tile closing practice.

Tile floor metal strip closed

U-shaped frame strips can be used to frame different materials such as floor tiles, stone, wooden floors, and carpets. It is made of aluminum alloy and generally has a width of 10mm. Today I mainly talk about the practice of ceramic tile metal closing.

The U-shaped necking strip can also be folded with stainless steel plate, and the width can reach 5-10mm.

The L-shaped metal strip is divided into grids, and the width can be reduced to 3-5mm.

The rubber strip in the middle can be used as an expansion joint for laying the ground.

For the closing strips with different ground elevations on both sides, the height of the metal strip should be determined according to the height difference on both sides.

Tile wall metal strip closed

In the past, we have often used 45 degree chamfers on wall tiles for butt joints. The control of construction quality lies in the construction operation of workers, and it is easy to bump during use, which will cause many quality problems. There used to be some projects that used some corners for docking, but the relative form is relatively simple and the material is relatively low (commonly used PVC, etc.).

For the closing of the external corners of marble and other stones, due to the machinability of the stone, the general engineering projects use 45-degree begonia angle touch, or edge grinding, bonding and other closing methods, and (unnecessary) metal strips are rarely used.

Here are some examples of metal closure practices in the outer corners of tiled walls:

It has the same form as the outer corner closing strip of the tile wall, the difference lies in the size. Because the thickness of the tile is different from that of the mosaic, and the thickness of the adhesive layer on the wall is not very large, generally around 5-8mm, it is suitable for the closing strip on the tile wall, but not suitable for the mosaic wall.

The yin and yang corner metal strips on the floor of the tile wall should be closed.

The inner corner of the wall and the ground is closed, usually in the form of wall pressing the ground, and there can be no upward joints. A cleaner, more aesthetically pleasing result is obtained with metal closure strips.

For tile floors such as stair treads, the outside corners are closed, and professional tread tiles are generally used, otherwise the outside corners cannot be handled. Custom metal closure strips can solve the closure of positive steps.

Through the preliminary combing of the metal shrinking strips, all the shrinking can not be used simply for shrinking, but should be closely related to the design scheme, use function, etc. To coordinate necking with functionality and aesthetics.

L Shape Tile Trims used between tiles or floorings for Transition and Decoration.

Stainless steel edge strip is bright and strong.For aluminum alloy trims,multi colors are available.Stainless steel,aluminum alloy and brass all have the specification of high corrosion resistance, high weather resistance and good wear resistance.PVC trims has cheap Price but the strength is a little bit low.

Our Stainless Steel L Shape Tile Trims is your best choice.If you are interested in our products, please contact us.

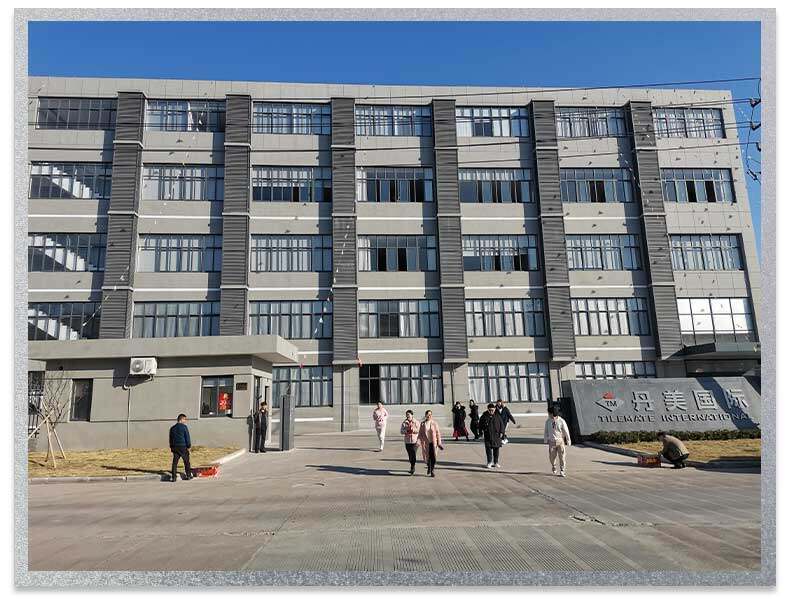

ABOUT US

BEAUTRIM was founded in 2002 and spacialize in producing building decorative products.Since its inception oriented manufacturing PVC profiles for curtain track,decoration and furniture.Then introduced increasing the range of aluminum products year after year.

In therecently years,new materials such as stainless steel, brass were introduced into our production line,weadopted new technology to produce kinds of profiles and developed many different finishes for stainless steel & brass profiles,we are sure these new products would be more and more popular in the world near future.

Today BEAUTRIM products exported to many countries in Europe,North&South America,Africa etc,BEAUTRIM is distinguished from its competitors by marketing positioning,we are the most windest production line,and we always try to provide best quality-price products and professional service to our customers at the field of construction.

We thank the trust that customers and suppliers have placed in BEAUTRIM and its products year after year,we believe that we must have a bright future in the field construction.

CERTIFICATE

PACKING &SHIPPING

by sea & by air, 25-30 days deliver time, stick protective film for each pcs.including stick lable. 20 pcs/ctn, 40 pcs/ctn, 60 pcs/ctn and 100 pcs/ctn all can.

FAQ

Q1:Are you a factory or a trading company?

A:Factory.

Q2:Where is your factory?

A:Ningbo, Zhejiang,China.

Q3:Are custom services available?

A:Yes.

Q4:Do you support OEM and ODM?

A:Yes.

Q5:Why choose us?

A:Our company has a professional R & D and design team,and we have rich experience in product production,Leading position in the industry.

Q6:Does your packaging ensure product safety?

A:We ship the profiles on pallets, which is very safe.

Q7:What information do I need to provide to get an accurate quote?

A:Material, thickness,weight for pcs finish & quantity etc.

Q8:How can I get product progress without going to your company?

A:Provide photos and videos in the production workshop.

Q9:How is your after-sales service?

A:According to the requirements of customers, try to meet them within the scope that can be achieved.

Q10:Can samples be ordered?

A:yes,can.

Q11:How much is the sample fee, can it be refunded after bulk product?

A:free samples.

Q12:Do you provide quality assurance?

A:yes.